008618900351519

hanxu422@163.com

No data

Most popular construction machine manufacturer since 1979 — JGM Machine

VIEW PRODUCTSWhy Are Electric Wheel Loaders More Cost-Effective? Where Exactly Does the Savings Come From?

May 30,2025

In current construction machinery industry, green technology and intelligent solutions have become the new engines driving sector development. Electric wheel loaders are steadily gaining market traction with their environmentally friendly design and cost-efficiency advantages.

Here we'll focus on the motor - the core component - to explore how electric wheel loaders achieve cost savings through motor maintenance.

A Simpler Motor Structure

Let's start by comparing the structural differences between motors and traditional internal combustion engines (ICE).

Electric motors in loaders feature a streamlined design, primarily consisting of stators, rotors, bearings, housings, cooling systems and terminal boxes. This simplified architecture results in fewer components, reduced failure rates and significantly easier maintenance procedures.

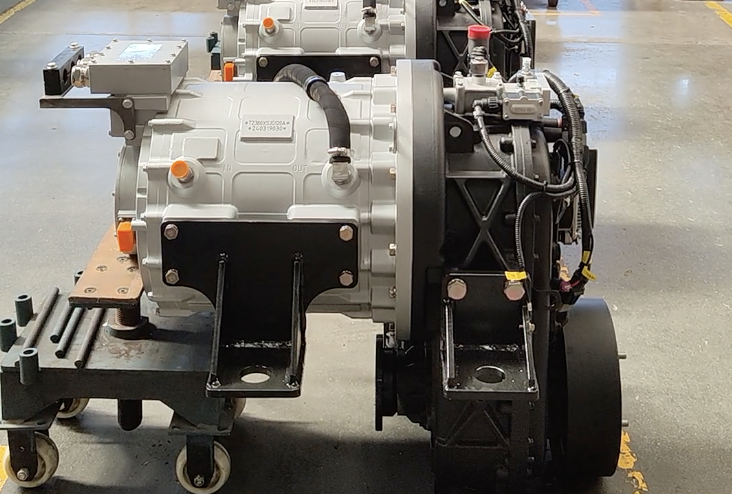

△ Jingong Electric Motor

By contrast, traditional ICEs contain complex systems including crankshaft-connecting rod mechanisms, valve trains, fuel delivery systems, lubrication systems, cooling systems, starting systems, turbochargers and electronic fuel injection systems. Each of these systems comprises multiple components, substantially increasing maintenance complexity and costs.

△ Internal Combustion Engines

Higher Energy Efficiency

Electric motors achieve direct and efficient energy conversion, transforming electrical energy into mechanical energy with minimal losses. This high-efficiency energy utilization not only improves operational productivity but also dramatically reduces energy consumption costs.

Traditional ICEs, which convert fuel combustion into thermal energy before transforming it into mechanical energy, generate significant waste heat. This requires additional oil for lubrication, complex cooling systems for heat dissipation and creates higher energy consumption burdens.

△ Jingong Electric Motor

Simplified Maintenance

ICE maintenance involves numerous complex tasks such as regular oil changes, oil filter replacements, fuel filter replacements, air filter inspections, cooling system checks, battery status monitoring, spark plug inspections, belt tension adjustments, etc.

Electric motor maintenance is significantly streamlined, requiring only basic operations like checking electrical connections, bearing lubrication and insulation resistance testing. This dramatic reduction in maintenance requirements directly lowers servicing costs while delivering substantial economic benefits!

△ Jingong Electric Wheel Loader

PREVIOUS:

Most popular construction machine manufacturer since 1979 — JGM Machine

HUATAO GROUP

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.